LED strobe has independent delay and duration

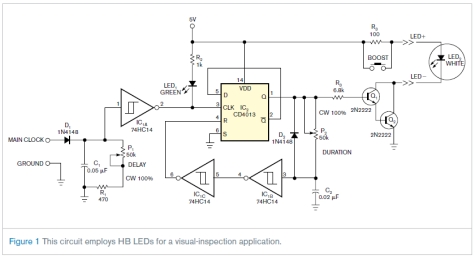

This circuit is not complex, but it was instrumental in an application involving the visual inspection of the spray pattern of fuel injectors for quality and consistency. In this application, xenon strobe lights were unsuitable due to their large size and the excessive intensity of light they emit.

The circuit described serves a critical role in the quality control of fuel injectors by facilitating the visual inspection of the spray pattern. The design is characterized by its simplicity, which makes it both cost-effective and easy to implement.

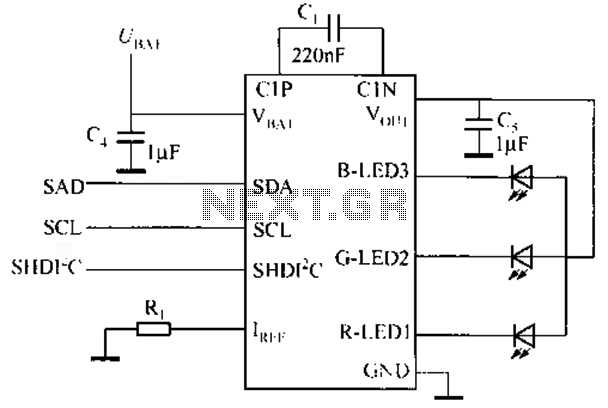

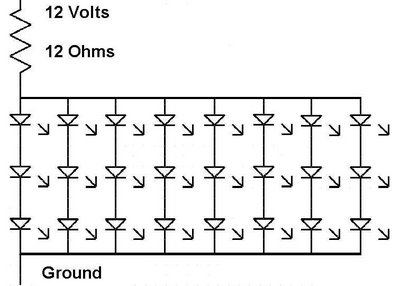

The circuit typically incorporates a low-power LED light source that is modulated to provide adequate illumination for the inspection process without overwhelming the observer. The choice of LED technology is significant, as LEDs offer a compact form factor and lower heat generation compared to traditional strobe lights. This allows the circuit to be integrated into tighter spaces where conventional lighting solutions would be impractical.

To achieve the desired visual effect, the circuit may include a microcontroller that regulates the LED's brightness and pulse width. This modulation can be adjusted to match the specific requirements of the inspection environment, ensuring that the fuel injector spray pattern is clearly visible without causing glare or reflections that could impede analysis.

Additionally, the circuit could employ a lens or optical filter to enhance the visibility of the spray pattern. This optical component would be designed to focus the emitted light onto the fuel injector, optimizing the viewing angle and intensity for the inspector.

In summary, the circuit is an effective solution for inspecting fuel injectors, providing a reliable and manageable alternative to xenon strobe lights. Its design focuses on compactness and control, ensuring that it meets the necessary requirements for quality assurance in fuel injection systems.This circuitis not complex, but it saved the day in an application involving visual inspection of the spray pattern of fuel injectors for quality and consistency. In this application, xenon strobe lights did not work because they take up too much space, and the light they emit is too intense.

🔗 External reference

The circuit described serves a critical role in the quality control of fuel injectors by facilitating the visual inspection of the spray pattern. The design is characterized by its simplicity, which makes it both cost-effective and easy to implement.

The circuit typically incorporates a low-power LED light source that is modulated to provide adequate illumination for the inspection process without overwhelming the observer. The choice of LED technology is significant, as LEDs offer a compact form factor and lower heat generation compared to traditional strobe lights. This allows the circuit to be integrated into tighter spaces where conventional lighting solutions would be impractical.

To achieve the desired visual effect, the circuit may include a microcontroller that regulates the LED's brightness and pulse width. This modulation can be adjusted to match the specific requirements of the inspection environment, ensuring that the fuel injector spray pattern is clearly visible without causing glare or reflections that could impede analysis.

Additionally, the circuit could employ a lens or optical filter to enhance the visibility of the spray pattern. This optical component would be designed to focus the emitted light onto the fuel injector, optimizing the viewing angle and intensity for the inspector.

In summary, the circuit is an effective solution for inspecting fuel injectors, providing a reliable and manageable alternative to xenon strobe lights. Its design focuses on compactness and control, ensuring that it meets the necessary requirements for quality assurance in fuel injection systems.This circuitis not complex, but it saved the day in an application involving visual inspection of the spray pattern of fuel injectors for quality and consistency. In this application, xenon strobe lights did not work because they take up too much space, and the light they emit is too intense.

🔗 External reference