pic16f877 based controllable digital clock using lcd display codeproteus simulation

This tutorial on the PIC16F877 microcontroller addresses the question, "How to implement a controllable digital clock using the PIC16F877?" It utilizes the PIC16 simulator for demonstration purposes.

The implementation of a controllable digital clock using the PIC16F877 microcontroller involves several key components and steps. The PIC16F877 is an 8-bit microcontroller with a variety of features that make it suitable for timing applications, such as built-in timers, I/O ports, and EEPROM for data storage.

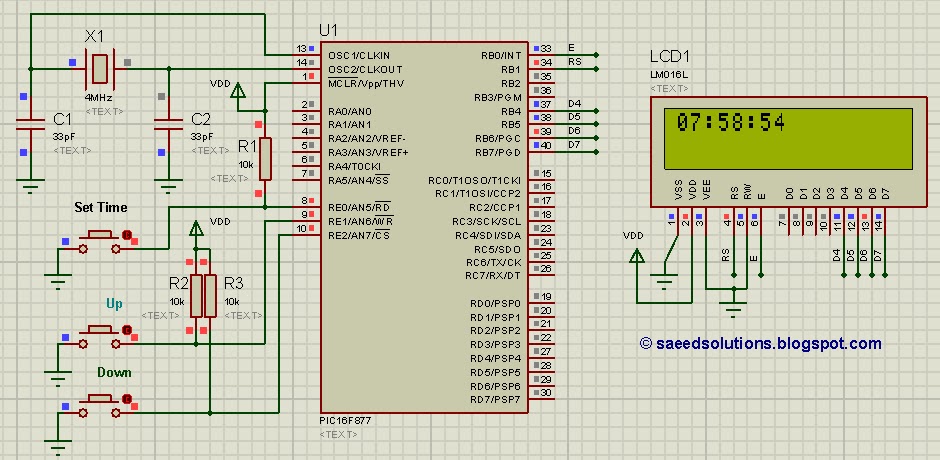

The circuit design begins with the microcontroller connected to a crystal oscillator to provide the necessary clock signal for accurate timing. A common frequency for the oscillator is 4 MHz, which allows the microcontroller to execute instructions efficiently. The oscillator circuit typically includes two capacitors connected to the crystal to stabilize the frequency.

The digital clock will require an interface for user input, which can be achieved using push buttons or a keypad. These inputs will allow users to set the time and switch between display modes (e.g., 12-hour or 24-hour format). The microcontroller's GPIO pins can be configured to read the state of these buttons.

For timekeeping, the microcontroller can utilize its internal timer modules. A timer interrupt can be configured to trigger every second, allowing the program to increment the time count accurately. The time can be stored in the microcontroller's RAM or EEPROM, depending on whether persistent storage is required.

The display of the clock can be implemented using a 7-segment LED display or an LCD module. The microcontroller will control the segments or characters displayed based on the current time value stored in memory. It is also essential to include a driver circuit for the display, especially if using multiple 7-segment displays, to handle the current requirements.

Power supply considerations are crucial for the clock circuit. A stable power source, such as a regulated 5V supply, should be used to ensure consistent operation. Additionally, the design may include a battery backup system to maintain time during power outages.

Lastly, the programming of the PIC16F877 can be accomplished using MPLAB IDE and XC8 compiler. The code will handle input reading, time calculation, display updates, and any additional features such as alarms or timers, providing a comprehensive solution for a controllable digital clock.This PIC16F877 microcontroller tutorial answers the question, "" How to implement a controllable digital clock using PIC16F877 ? "" Using PIC16 simulator (Pr.. 🔗 External reference

The implementation of a controllable digital clock using the PIC16F877 microcontroller involves several key components and steps. The PIC16F877 is an 8-bit microcontroller with a variety of features that make it suitable for timing applications, such as built-in timers, I/O ports, and EEPROM for data storage.

The circuit design begins with the microcontroller connected to a crystal oscillator to provide the necessary clock signal for accurate timing. A common frequency for the oscillator is 4 MHz, which allows the microcontroller to execute instructions efficiently. The oscillator circuit typically includes two capacitors connected to the crystal to stabilize the frequency.

The digital clock will require an interface for user input, which can be achieved using push buttons or a keypad. These inputs will allow users to set the time and switch between display modes (e.g., 12-hour or 24-hour format). The microcontroller's GPIO pins can be configured to read the state of these buttons.

For timekeeping, the microcontroller can utilize its internal timer modules. A timer interrupt can be configured to trigger every second, allowing the program to increment the time count accurately. The time can be stored in the microcontroller's RAM or EEPROM, depending on whether persistent storage is required.

The display of the clock can be implemented using a 7-segment LED display or an LCD module. The microcontroller will control the segments or characters displayed based on the current time value stored in memory. It is also essential to include a driver circuit for the display, especially if using multiple 7-segment displays, to handle the current requirements.

Power supply considerations are crucial for the clock circuit. A stable power source, such as a regulated 5V supply, should be used to ensure consistent operation. Additionally, the design may include a battery backup system to maintain time during power outages.

Lastly, the programming of the PIC16F877 can be accomplished using MPLAB IDE and XC8 compiler. The code will handle input reading, time calculation, display updates, and any additional features such as alarms or timers, providing a comprehensive solution for a controllable digital clock.This PIC16F877 microcontroller tutorial answers the question, "" How to implement a controllable digital clock using PIC16F877 ? "" Using PIC16 simulator (Pr.. 🔗 External reference