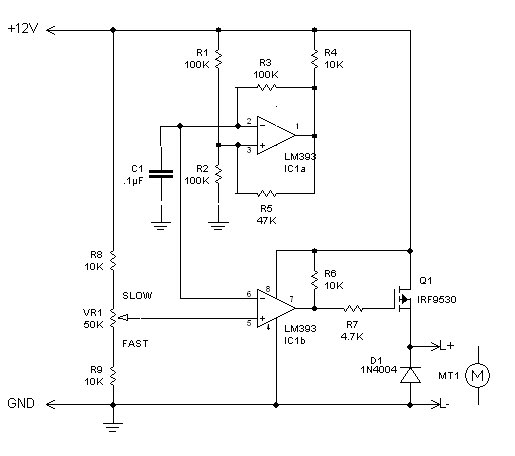

PWM circuit

The inquiry pertains to identifying the component within the circuit that regulates the minimum RPM achievable. The current operational range of the motor is between 1400 and 3700 RPM, and there is an interest in modifying the circuit to lower the RPM slightly.

The control of the minimum RPM in a motor circuit typically involves several key components, including the speed controller, feedback systems, and possibly the motor type itself. In a standard PWM (Pulse Width Modulation) motor control circuit, the duty cycle of the PWM signal directly influences the average voltage applied to the motor, thus affecting its speed. By adjusting the duty cycle, it is possible to lower the minimum RPM.

To achieve a lower RPM, one can consider the following approaches:

1. **PWM Frequency Adjustment**: Lowering the PWM frequency can allow for smoother control at lower speeds. However, this may introduce issues such as increased heat generation and reduced efficiency.

2. **Feedback Loop Modification**: If the circuit employs a feedback loop (for example, using a tachometer), adjusting the feedback parameters can help achieve a more stable operation at lower speeds. This may involve tuning the PID (Proportional-Integral-Derivative) controller settings to ensure the motor can respond effectively at reduced speeds.

3. **Motor Characteristics**: The type of motor used (e.g., brushed vs. brushless, stepper, or servo) will also affect the ability to run at low RPMs. Some motors have inherent limitations in their speed range due to their design.

4. **Additional Components**: Incorporating additional components such as resistors or capacitors in the control circuit can help fine-tune the performance. For example, adding a resistor in series with the motor can limit the current, thereby reducing the speed.

5. **Software Control**: If the circuit is controlled by a microcontroller, programming adjustments can be made to the control algorithm to allow for lower speed settings.

In summary, controlling the minimum RPM of a motor circuit involves a combination of hardware modifications and software adjustments. It is essential to analyze the specific circuit design and motor characteristics to determine the most effective method for achieving the desired lower RPM range.My question is what part of the circuit controls the lowest rpm that can be achieved with your circuit? I`m getting a range of 1400-3700 rpm on my motor with your circuit and want to tinker it a little bit for a slightly lower rpm.

🔗 External reference

The control of the minimum RPM in a motor circuit typically involves several key components, including the speed controller, feedback systems, and possibly the motor type itself. In a standard PWM (Pulse Width Modulation) motor control circuit, the duty cycle of the PWM signal directly influences the average voltage applied to the motor, thus affecting its speed. By adjusting the duty cycle, it is possible to lower the minimum RPM.

To achieve a lower RPM, one can consider the following approaches:

1. **PWM Frequency Adjustment**: Lowering the PWM frequency can allow for smoother control at lower speeds. However, this may introduce issues such as increased heat generation and reduced efficiency.

2. **Feedback Loop Modification**: If the circuit employs a feedback loop (for example, using a tachometer), adjusting the feedback parameters can help achieve a more stable operation at lower speeds. This may involve tuning the PID (Proportional-Integral-Derivative) controller settings to ensure the motor can respond effectively at reduced speeds.

3. **Motor Characteristics**: The type of motor used (e.g., brushed vs. brushless, stepper, or servo) will also affect the ability to run at low RPMs. Some motors have inherent limitations in their speed range due to their design.

4. **Additional Components**: Incorporating additional components such as resistors or capacitors in the control circuit can help fine-tune the performance. For example, adding a resistor in series with the motor can limit the current, thereby reducing the speed.

5. **Software Control**: If the circuit is controlled by a microcontroller, programming adjustments can be made to the control algorithm to allow for lower speed settings.

In summary, controlling the minimum RPM of a motor circuit involves a combination of hardware modifications and software adjustments. It is essential to analyze the specific circuit design and motor characteristics to determine the most effective method for achieving the desired lower RPM range.My question is what part of the circuit controls the lowest rpm that can be achieved with your circuit? I`m getting a range of 1400-3700 rpm on my motor with your circuit and want to tinker it a little bit for a slightly lower rpm.

🔗 External reference