Stepper

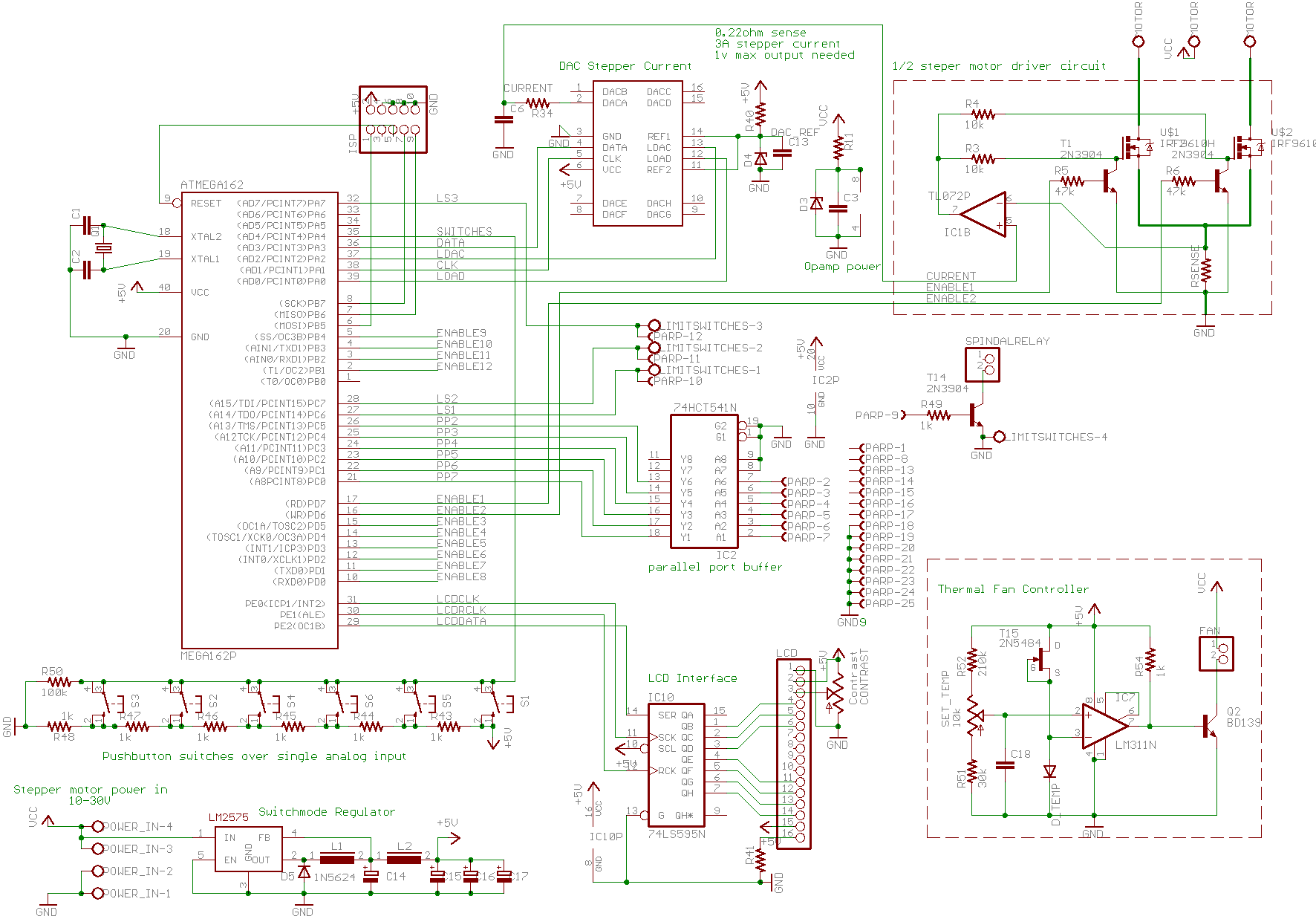

The resistors R18 and R22, which were intended to be connected to pin 8 of U4, were incorrectly connected to pin 9. The current versions have been corrected. There is a minor error in the component layout where two versions of C2 appear in the upper right and lower left corners; one of them should be labeled C11 instead, as they are identical. This correction is not reflected in the image. The latest schematic has been updated with part numbering by David H Bevel, although there may be occasional oversights. This schematic, along with the parts list and PCB layout (available in full scale at 500 dpi or a 1:4 version for viewing), is consistent across the component layout and timing diagram. An alternate PCB pattern with less copper etched away is also available. A diagram of the connections and a picture of the assembled version by Dave are included. Future modifications will enable the use of a low-voltage stepper motor with a 3V supply and a 12V control circuit. This circuit was originally designed to operate a 5.25" floppy-disk type stepper motor driving a threaded rod, but it may be adapted for other platform designs. It has been utilized with an equatorial platform for 13.1" and 6" Dobsonian telescopes, providing a useful addition for planetary studies without the need for constant repositioning of the telescope. The previous full-step circuit introduced vibrations that compromised detail, especially with the 6" telescope. While increasing the speed with more gearing might have been a solution, a fast rewind with the threaded rod driver was needed, as three minutes of rewind after an hour of use was approaching the limit of acceptability. An interface circuit for Mel Bartels' Scope Drive was developed as a pilot project before attempting it with Dobsonian telescopes. This experimentation has led to the creation of a computer-controlled tester stage for Foucault and related tests. After testing pulse-width modulation, a different approach was adopted, incorporating a 3-bit D-A converter for analog microstepping, resulting in smoother motion. The design aims for a speed of 1.75 turns/min or 0.029 turns/sec, translating to 5.8 full steps/second with a 200-step motor and no gearing. This results in a celestial motion of approximately 2.6 arcseconds per full step, exceeding the resolution of the telescope at 0.7 arcseconds, which has been problematic due to resonances in the 6" telescope.

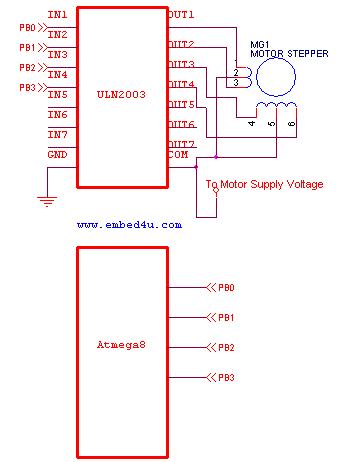

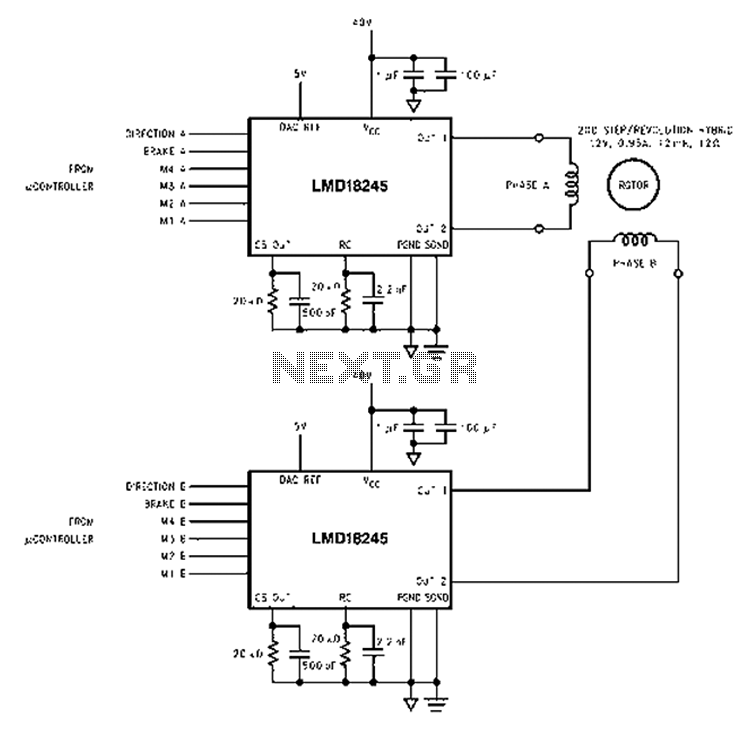

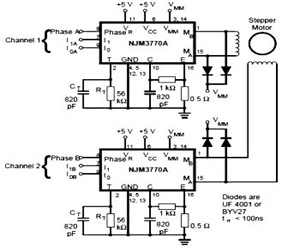

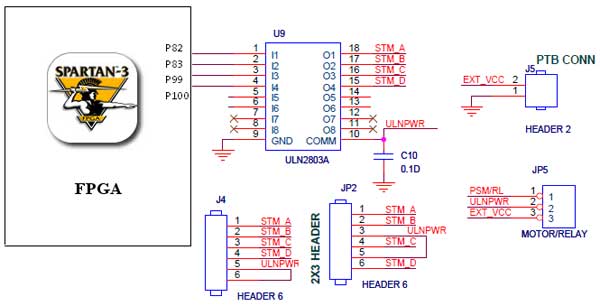

The circuit design incorporates a stepper motor driver that utilizes a microstepping approach to enhance motion smoothness and precision. The driver operates by controlling the current through the motor windings, allowing for finer control over the stepper motor's position. The D-A converter plays a crucial role in translating digital signals into analog currents, enabling the driver to energize specific windings based on the desired step position.

In terms of layout, careful consideration is given to the placement of components to minimize interference and optimize performance. The PCB design should facilitate efficient heat dissipation and accommodate the required voltage levels for both the stepper motor and control circuitry. The use of decoupling capacitors near the power supply pins of the ICs ensures stability during operation, reducing noise that could affect the performance of the stepper motor.

The timing diagram included in the documentation illustrates the sequence of control signals sent to the stepper motor, highlighting the timing relationships between different phases of operation. This is critical for ensuring that the motor operates smoothly and accurately follows the intended trajectory during celestial tracking.

Future enhancements may involve integrating feedback mechanisms for improved accuracy, such as optical encoders that provide real-time position data to the control system. This would allow for closed-loop control, further enhancing the system's performance and reliability in astronomical applications.The resistors R18 and R22 that should have been connected to pin 8 of U4 were mistakenly connected to pin 9. The present versions have been corrected. A minor error on the component layout is that there are two versions of C2, in the upper right and lower left corners - let one of them read C11 instead (they are equal).

This is not corrected on the image. Here is the latest schematic by David H Bevel - I have updated the text with his parts numbering (I hope, but I may have missed occasionally!). This schematic, the parts list and the PCB pattern (Full scale at 500 dpi - or a 1:4 version for viewing ) (note that the pattern is seen from the component, NOT the copper side!) and an alternate PCB pattern with less copper etched away, as well as the component layout and the timing diagram are mutually consistent - I am sure. Also, here is a diagram of the connections and a picture of Dave`s version built and ready - Thanks a lot Dave for all the work you`ve done !

Folks, please respect our copyrights. Next in the pipeline - the modification necessary to use a low-voltage stepper motor using 3V supply (and 12v for the control circuit). If this is of interest to you, mail me at nilsolof. carlin@telia. com. This circuit was designed primarily to feed a 5. 25" floppy-disk type stepper, driving a threaded rod, but may be used with other platform designs. It features: I`ve been using an equatorial platform for my 13. 1" and 6" Dobs. I consider the platform a very useful addition - a full GoTo mount can do more, but I think the mechanical complexity is also in another league.

It is of course particularly useful for planet studies - not least if you like to show planets to friends and acquaintances, as you do not need to re-position the telescope every minute! However, the full-step circuit I have been using (until I made the circuit described here) introduces enough vibration to wipe out much of the detail (particularly with my 6"), and I`ve been wishing for a better driver.

Running the stepper faster using more gearing down might have helped, but I wanted a fast rewind with my threaded rod driver, and some 3 minutes of rewind after an hour of use was already near the limit of acceptability. Recently I started to build an interface circuit for Mel Bartels` Scope Drive, to use with my old SP-C6 as a pilot project before trying with my Dobs (the stepper motors and mechanics are already there, and no position feedback is needed - but the gearing seems to preclude fast slewing.

). Experimenting with this has already produced interesting spin-off in the form of a computer controlled tester stage for Foucault and related tests described elsewhere. After experimenting with pulse-width modulation, it was quite clear to me that I should try a different approach (with all respect to Mel, though I admit that the pulse-width modulation he uses does work, but it is very noisy!).

I attached a 3-bit (plus sign bit to decide which half of the winding to energize) D-A converter, using analog microstepping. Not quite unexpectedly, I found the motion of this very much smoother. So on to designing a circuit - it was a long while ago since I did much electronic design, but I had a lot of components left.

, meaning it should turn 1. 75 turns/min or 0. 029 turns/sec - with a 200 step motor (and no gears) this means 5. 8 full steps/second. This means the stars near the celestial equator will move 15/5. 8 ~ 2. 6 arcsec/fullstep, far more than the resolution of the telescope at 0. 7 arcsec of Dawes` limit for my 6". With my old driver I used a primitive gear of appr 6:1, giving a celestial motion of 0. 4 arcsec between steps - clearly, resonances in my 6" amplified this. Vib 🔗 External reference

The circuit design incorporates a stepper motor driver that utilizes a microstepping approach to enhance motion smoothness and precision. The driver operates by controlling the current through the motor windings, allowing for finer control over the stepper motor's position. The D-A converter plays a crucial role in translating digital signals into analog currents, enabling the driver to energize specific windings based on the desired step position.

In terms of layout, careful consideration is given to the placement of components to minimize interference and optimize performance. The PCB design should facilitate efficient heat dissipation and accommodate the required voltage levels for both the stepper motor and control circuitry. The use of decoupling capacitors near the power supply pins of the ICs ensures stability during operation, reducing noise that could affect the performance of the stepper motor.

The timing diagram included in the documentation illustrates the sequence of control signals sent to the stepper motor, highlighting the timing relationships between different phases of operation. This is critical for ensuring that the motor operates smoothly and accurately follows the intended trajectory during celestial tracking.

Future enhancements may involve integrating feedback mechanisms for improved accuracy, such as optical encoders that provide real-time position data to the control system. This would allow for closed-loop control, further enhancing the system's performance and reliability in astronomical applications.The resistors R18 and R22 that should have been connected to pin 8 of U4 were mistakenly connected to pin 9. The present versions have been corrected. A minor error on the component layout is that there are two versions of C2, in the upper right and lower left corners - let one of them read C11 instead (they are equal).

This is not corrected on the image. Here is the latest schematic by David H Bevel - I have updated the text with his parts numbering (I hope, but I may have missed occasionally!). This schematic, the parts list and the PCB pattern (Full scale at 500 dpi - or a 1:4 version for viewing ) (note that the pattern is seen from the component, NOT the copper side!) and an alternate PCB pattern with less copper etched away, as well as the component layout and the timing diagram are mutually consistent - I am sure. Also, here is a diagram of the connections and a picture of Dave`s version built and ready - Thanks a lot Dave for all the work you`ve done !

Folks, please respect our copyrights. Next in the pipeline - the modification necessary to use a low-voltage stepper motor using 3V supply (and 12v for the control circuit). If this is of interest to you, mail me at nilsolof. carlin@telia. com. This circuit was designed primarily to feed a 5. 25" floppy-disk type stepper, driving a threaded rod, but may be used with other platform designs. It features: I`ve been using an equatorial platform for my 13. 1" and 6" Dobs. I consider the platform a very useful addition - a full GoTo mount can do more, but I think the mechanical complexity is also in another league.

It is of course particularly useful for planet studies - not least if you like to show planets to friends and acquaintances, as you do not need to re-position the telescope every minute! However, the full-step circuit I have been using (until I made the circuit described here) introduces enough vibration to wipe out much of the detail (particularly with my 6"), and I`ve been wishing for a better driver.

Running the stepper faster using more gearing down might have helped, but I wanted a fast rewind with my threaded rod driver, and some 3 minutes of rewind after an hour of use was already near the limit of acceptability. Recently I started to build an interface circuit for Mel Bartels` Scope Drive, to use with my old SP-C6 as a pilot project before trying with my Dobs (the stepper motors and mechanics are already there, and no position feedback is needed - but the gearing seems to preclude fast slewing.

). Experimenting with this has already produced interesting spin-off in the form of a computer controlled tester stage for Foucault and related tests described elsewhere. After experimenting with pulse-width modulation, it was quite clear to me that I should try a different approach (with all respect to Mel, though I admit that the pulse-width modulation he uses does work, but it is very noisy!).

I attached a 3-bit (plus sign bit to decide which half of the winding to energize) D-A converter, using analog microstepping. Not quite unexpectedly, I found the motion of this very much smoother. So on to designing a circuit - it was a long while ago since I did much electronic design, but I had a lot of components left.

, meaning it should turn 1. 75 turns/min or 0. 029 turns/sec - with a 200 step motor (and no gears) this means 5. 8 full steps/second. This means the stars near the celestial equator will move 15/5. 8 ~ 2. 6 arcsec/fullstep, far more than the resolution of the telescope at 0. 7 arcsec of Dawes` limit for my 6". With my old driver I used a primitive gear of appr 6:1, giving a celestial motion of 0. 4 arcsec between steps - clearly, resonances in my 6" amplified this. Vib 🔗 External reference