Telephone motor Controller

This Project is used to control a single phase Motor from any where in the world through the telephone. The circuit consists of a DTMF tone detector and a powerful 8 bit Microcontroller AT89S52. The Microcontroller senses the DTMF signal through the DTMF decoder IC MT8870 and it switches on/off and speeds up/down the motor according to the user need. The circuit has an inbuilt Phone Ring sensor circuit and the system will take over the phone control if it was not taken manually for more than 5 rings. The DTMF decoder decodes the DTMF tones into digital signal and this signal was fed to the Microcontroller and according to this signal the microcontroller will control the Motor with help of the TRIAC. The system is fully password protected so the user can...

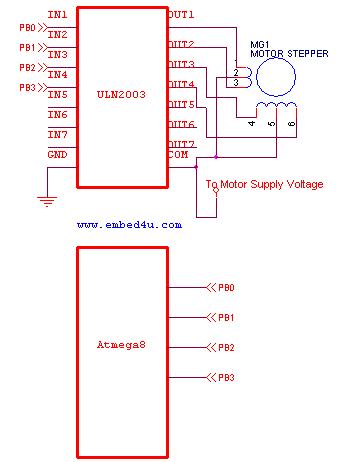

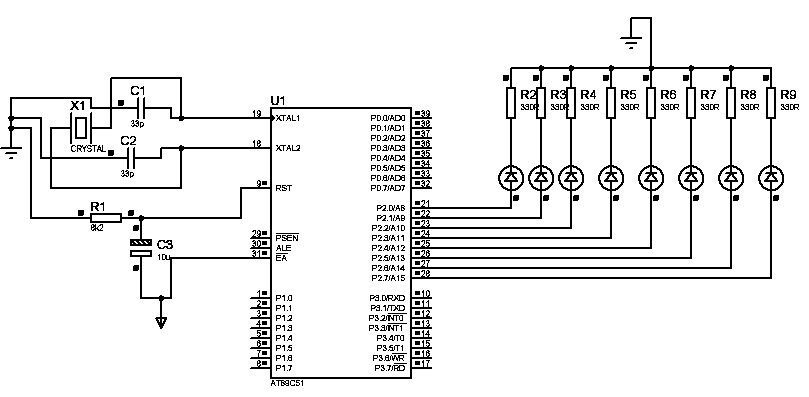

The circuit design involves several key components that interact to provide remote control of a single-phase motor via telephone using DTMF (Dual Tone Multi-Frequency) signaling. The primary component is the AT89S52 microcontroller, which serves as the central processing unit. This 8-bit microcontroller is programmed to interpret the DTMF signals received from the MT8870 DTMF decoder, which converts the audio tones generated by a telephone keypad into corresponding digital signals.

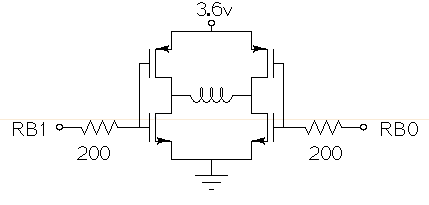

The DTMF decoder MT8870 is connected to the microcontroller's input pins, allowing the microcontroller to read the decoded signals. Each DTMF tone corresponds to a specific command, such as starting or stopping the motor, or adjusting its speed. The microcontroller processes these commands and generates the appropriate output signals to control a TRIAC, which is used to manage the power supplied to the motor. The TRIAC is selected for its ability to handle AC loads and provide efficient control over the motor's operation.

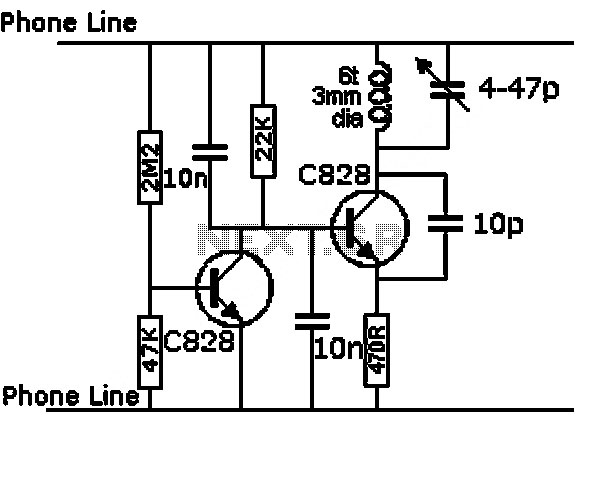

In addition to the DTMF control, the circuit includes a phone ring sensor. This sensor monitors incoming calls and detects the ringing signal. If the phone is not answered manually after five rings, the system automatically takes control, allowing the user to operate the motor without needing to pick up the phone. This feature is particularly useful for remote operations, ensuring that the system can respond to commands even when the user is unavailable.

Security is a critical aspect of this design. The system is equipped with a password protection mechanism, which ensures that only authorized users can control the motor. This is achieved by requiring a specific DTMF sequence to be entered before any motor commands are executed. The implementation of this security feature adds an additional layer of protection against unauthorized access.

Overall, this project combines telecommunications and microcontroller technology to create a versatile and user-friendly system for controlling a single-phase motor remotely. The integration of DTMF signaling, microcontroller logic, and TRIAC switching provides a robust solution for various applications where motor control is needed from a distance.This Project is used to control a single phase Motor from any where in the world through the telephone. The circuit consists of a DTMF tone detector and a powerful 8 bit Microcontroller AT89S52. The Microcontroller senses the DTMF signal through the DTMF decoder IC MT8870 and it switch on/off and speed up/down the motor according to the user need.

The circuit has an inbuilt Phone Ring sensor circuit and the system will take over the phone control if it was not taken manually for more than 5 rings. The DTMF decoder decodes the DTMF tones into digital signal and this signal was fed to the Microcontroller and according to this signal the microcontroller will control the Motor with help of the TRIAC The system is fully password protected so the user c 🔗 External reference

The circuit design involves several key components that interact to provide remote control of a single-phase motor via telephone using DTMF (Dual Tone Multi-Frequency) signaling. The primary component is the AT89S52 microcontroller, which serves as the central processing unit. This 8-bit microcontroller is programmed to interpret the DTMF signals received from the MT8870 DTMF decoder, which converts the audio tones generated by a telephone keypad into corresponding digital signals.

The DTMF decoder MT8870 is connected to the microcontroller's input pins, allowing the microcontroller to read the decoded signals. Each DTMF tone corresponds to a specific command, such as starting or stopping the motor, or adjusting its speed. The microcontroller processes these commands and generates the appropriate output signals to control a TRIAC, which is used to manage the power supplied to the motor. The TRIAC is selected for its ability to handle AC loads and provide efficient control over the motor's operation.

In addition to the DTMF control, the circuit includes a phone ring sensor. This sensor monitors incoming calls and detects the ringing signal. If the phone is not answered manually after five rings, the system automatically takes control, allowing the user to operate the motor without needing to pick up the phone. This feature is particularly useful for remote operations, ensuring that the system can respond to commands even when the user is unavailable.

Security is a critical aspect of this design. The system is equipped with a password protection mechanism, which ensures that only authorized users can control the motor. This is achieved by requiring a specific DTMF sequence to be entered before any motor commands are executed. The implementation of this security feature adds an additional layer of protection against unauthorized access.

Overall, this project combines telecommunications and microcontroller technology to create a versatile and user-friendly system for controlling a single-phase motor remotely. The integration of DTMF signaling, microcontroller logic, and TRIAC switching provides a robust solution for various applications where motor control is needed from a distance.This Project is used to control a single phase Motor from any where in the world through the telephone. The circuit consists of a DTMF tone detector and a powerful 8 bit Microcontroller AT89S52. The Microcontroller senses the DTMF signal through the DTMF decoder IC MT8870 and it switch on/off and speed up/down the motor according to the user need.

The circuit has an inbuilt Phone Ring sensor circuit and the system will take over the phone control if it was not taken manually for more than 5 rings. The DTMF decoder decodes the DTMF tones into digital signal and this signal was fed to the Microcontroller and according to this signal the microcontroller will control the Motor with help of the TRIAC The system is fully password protected so the user c 🔗 External reference