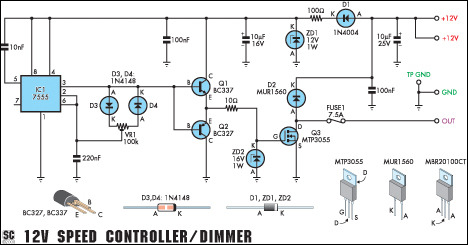

12v speed controllerdimmer

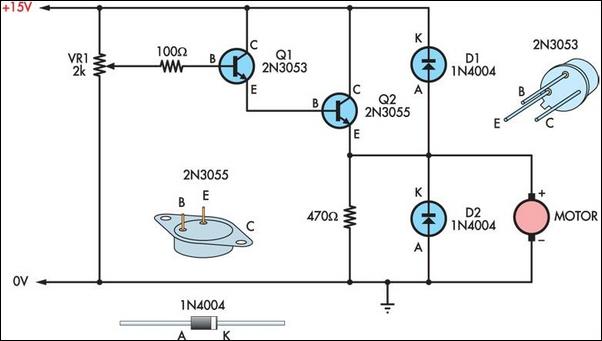

This versatile circuit functions as a speed controller for a 12V motor with a continuous rating of up to 5A or as a dimmer for a 12V halogen or standard incandescent lamp with a maximum rating of 50W. It adjusts the power supplied to the load (either the motor or the lamp) by employing pulse width modulation (PWM) at a pulse frequency of approximately 220Hz.

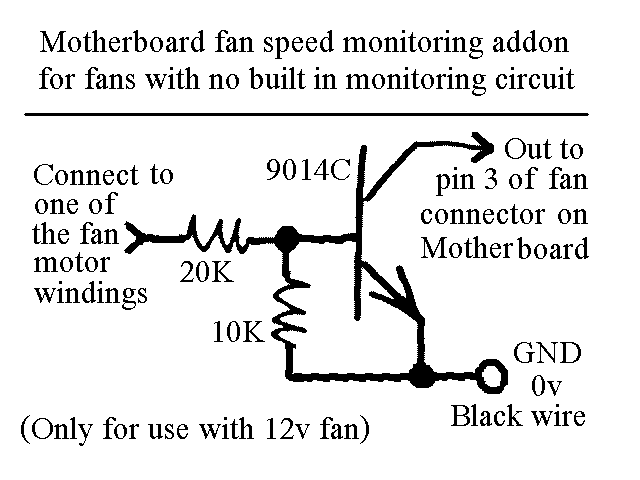

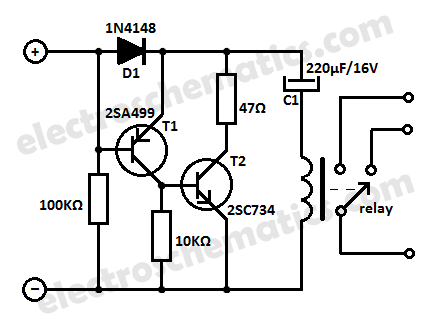

The circuit utilizes a PWM technique to modulate the voltage applied to the load, allowing for precise control over the speed of the motor or the brightness of the lamp. The key components typically include a microcontroller or a dedicated PWM controller IC, a MOSFET or transistor for switching, and necessary passive components such as resistors and capacitors to filter and stabilize the PWM signal.

For a 12V motor, the circuit can efficiently manage the motor's speed by adjusting the duty cycle of the PWM signal; a higher duty cycle results in increased speed, while a lower duty cycle slows the motor down. The circuit should be designed to handle the thermal and electrical characteristics of the motor, ensuring that the switching device can manage the continuous current without overheating.

When used as a dimmer for lamps, the circuit similarly adjusts the brightness by varying the average power delivered to the lamp. It is crucial to ensure that the PWM frequency is suitable for the type of lamp used, as some lamps may flicker at certain frequencies. The 220Hz frequency is generally effective for most incandescent and halogen lamps, providing smooth dimming without visible flicker.

Overall, this circuit is a practical solution for applications requiring variable speed control or brightness adjustment, making it suitable for various electronic projects and industrial applications. Proper design and implementation are essential to ensure reliability and performance under the specified load conditions.This handy circuit can be used as a speed controller for a 12V motor rated up to 5A (continuous) or as a dimmer for a 12V halogen or standard incandescent lamp rated up to 50W. It varies the power to the load (motor or lamp) using pulse width modulation (PWM) at a pulse frequency of around 220Hz..

🔗 External reference

The circuit utilizes a PWM technique to modulate the voltage applied to the load, allowing for precise control over the speed of the motor or the brightness of the lamp. The key components typically include a microcontroller or a dedicated PWM controller IC, a MOSFET or transistor for switching, and necessary passive components such as resistors and capacitors to filter and stabilize the PWM signal.

For a 12V motor, the circuit can efficiently manage the motor's speed by adjusting the duty cycle of the PWM signal; a higher duty cycle results in increased speed, while a lower duty cycle slows the motor down. The circuit should be designed to handle the thermal and electrical characteristics of the motor, ensuring that the switching device can manage the continuous current without overheating.

When used as a dimmer for lamps, the circuit similarly adjusts the brightness by varying the average power delivered to the lamp. It is crucial to ensure that the PWM frequency is suitable for the type of lamp used, as some lamps may flicker at certain frequencies. The 220Hz frequency is generally effective for most incandescent and halogen lamps, providing smooth dimming without visible flicker.

Overall, this circuit is a practical solution for applications requiring variable speed control or brightness adjustment, making it suitable for various electronic projects and industrial applications. Proper design and implementation are essential to ensure reliability and performance under the specified load conditions.This handy circuit can be used as a speed controller for a 12V motor rated up to 5A (continuous) or as a dimmer for a 12V halogen or standard incandescent lamp rated up to 50W. It varies the power to the load (motor or lamp) using pulse width modulation (PWM) at a pulse frequency of around 220Hz..

🔗 External reference