Automatic toilet flushing circuit

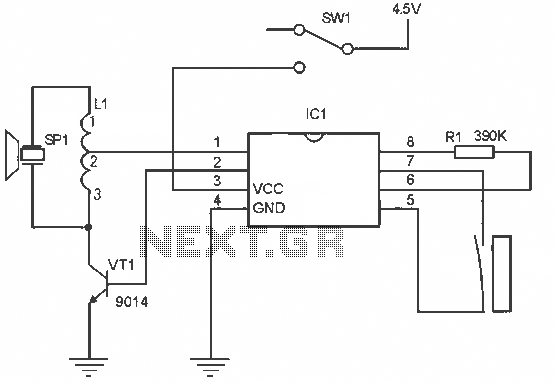

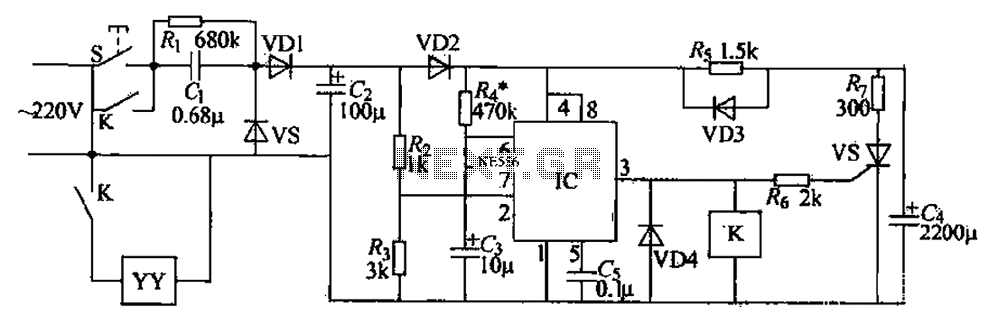

The automatic toilet flusher is designed to restructure the traditional flushing mechanism, allowing for a single, reliable flush after each use. It features energy-saving capabilities and a long-lasting chip, ensuring ease of use even when disconnected from the power source. The circuit includes a power circuit, a monostable solenoid valve, and a control circuit. The power circuit consists of a step-down capacitor (C1), a rectifier diode (VD1), a Zener diode, and a filtering capacitor (C2), among other components. The operation begins when the toilet lid is opened, activating switch S, which allows AC 220V voltage to pass through the circuit. This voltage is then rectified by VD1, regulated, and filtered to power the system. The monostable circuit, built around an integrated circuit (IC) and its associated components, is triggered when the voltage at terminal IC1 exceeds Vcc/3, causing the output to go low and preventing the relay (K) from activating while charging the large-capacity capacitor. Once the toilet lid is closed, switch S turns off, cutting the power. The isolation provided by VD2 allows the capacitor to discharge quickly, triggering the IC. In this scenario, the bulk capacitor supplies power to the IC through diode VD3, activating the one-shot circuit and resulting in the relay K being energized. This action restores power to the circuit and activates the solenoid valve (Y) to initiate flushing. Meanwhile, the power supply charges capacitor C3, which, upon reaching a certain voltage (2Vcc/3), temporarily ends the state, causing the IC output to return low and the relay K to deactivate, cutting power to the circuit and completing the flush cycle. A thyristor (VTH) discharges to ensure a single flush. When the IC transitions from low to high, VTH triggers conduction, reducing the discharge voltage. If the discharge circuit is engaged, the relay K will release, disconnecting the circuit, allowing the IC to receive power from VD3, and repeating the trigger cycle.

The automatic toilet flusher circuit operates on a straightforward yet effective principle, integrating various electronic components to ensure reliable performance. The power circuit is crucial, consisting of a step-down capacitor (C1) that reduces the input voltage, a rectifier diode (VD1) that converts AC to DC, and a Zener diode that regulates the output voltage. The filtering capacitor (C2) smooths the voltage supply, ensuring stable operation of the circuit.

The monostable circuit is the heart of the flushing mechanism. It utilizes an integrated circuit (IC) that responds to voltage levels at its input pins. When the toilet lid is opened, the switch S is activated, allowing the power supply to charge the system. The IC monitors the voltage levels, and when the voltage at the trigger pin exceeds a third of the supply voltage (Vcc/3), it changes the output state, allowing the relay K to remain inactive while the capacitor charges.

Upon closing the toilet lid, the power is cut off, but the isolation diode (VD2) allows the capacitor to discharge through the resistor (Rz), triggering the IC. This transition activates the relay K, which connects the power supply to the solenoid valve (Y), initiating the flushing process. The system is designed to ensure that the flush occurs only once per use, thanks to the thyristor (VTH) that discharges and prevents multiple activations.

The timing and control of the flush are managed by the charging of capacitor C3, which, when charged to a specific voltage, causes the IC output to revert, deactivating the relay and cutting power to the circuit. This design allows for efficient energy management and ensures that the automatic toilet flusher operates smoothly and reliably, providing a user-friendly experience while conserving power. Automatic toilet flusher is restructuring in the sitting so that the basis of the ordinary, the automatic flush after use once, simple and reliable. When not in power source co mpletely disconnected, with energy-saving, easy to use, long life chip advantage. (1) circuit automatic flush toilet circuit from the power circuit, monostable solenoid valve and control circuit, as shown 1-47 Fig. Power circuit consists of step-down capacitor C1, rectifier diode VD1, Zener diode and capacitor C2 vs other components.

(2) the work process open toilet lid, the switch S is turned on, AC 220V voltage by cI Buck, VD1 rectifier, vs regulator and G after filtering, to provide the power supply circuit.. . : Monostable circuit from when base integrated circuit lc and relevant peripheral components. foot trigger terminal 1C initial voltage by Rz, R3 partial pressure is higher than after Vcc/3, lC the pin output low, the single-shot in the steady state, the relay K is not action, large-capacity capacitor is charged 0 full power.

After use, when the toilet lid cover, switch S off, the circuit power outages, due to the isolation of VD2 charge cz Rz on the quickly let go and Po. lC of pin goes low is triggered. In this case the bulk capacitor G is the IC supply through diode VD3, one-shot circuit is triggered transient backward people, ICs pin goes high, the relay K leisure together.

After K closed self-locking, so that the circuit to restore power supply, K closed connected to electric solenoid valve Y, start flushing. Meanwhile, the power supply via a resistor horse C3 charging, when charging so C3 rises to the potential of pin IC 2Vcc/3 resistance, temporary end state, lC of foot turned back low, the relay K release, K OFF, the The entire circuit power, flush ends.

Used in the circuit of the thyristor VTH G discharge, ensure that only flush once. When the IC foot just flip from low to high, VTH is triggered conduction, the G discharge voltage drops 2 ~ 3V. If set G discharge circuit, the lC after the transient, the relay K release put, K suddenly disconnected the circuit energized, ICs feet and jump into a low, G by VD3 supplies power to lC, single steady circuit again and again by the trigger, and pull the relay K, and so forth cycle.

The automatic toilet flusher circuit operates on a straightforward yet effective principle, integrating various electronic components to ensure reliable performance. The power circuit is crucial, consisting of a step-down capacitor (C1) that reduces the input voltage, a rectifier diode (VD1) that converts AC to DC, and a Zener diode that regulates the output voltage. The filtering capacitor (C2) smooths the voltage supply, ensuring stable operation of the circuit.

The monostable circuit is the heart of the flushing mechanism. It utilizes an integrated circuit (IC) that responds to voltage levels at its input pins. When the toilet lid is opened, the switch S is activated, allowing the power supply to charge the system. The IC monitors the voltage levels, and when the voltage at the trigger pin exceeds a third of the supply voltage (Vcc/3), it changes the output state, allowing the relay K to remain inactive while the capacitor charges.

Upon closing the toilet lid, the power is cut off, but the isolation diode (VD2) allows the capacitor to discharge through the resistor (Rz), triggering the IC. This transition activates the relay K, which connects the power supply to the solenoid valve (Y), initiating the flushing process. The system is designed to ensure that the flush occurs only once per use, thanks to the thyristor (VTH) that discharges and prevents multiple activations.

The timing and control of the flush are managed by the charging of capacitor C3, which, when charged to a specific voltage, causes the IC output to revert, deactivating the relay and cutting power to the circuit. This design allows for efficient energy management and ensures that the automatic toilet flusher operates smoothly and reliably, providing a user-friendly experience while conserving power. Automatic toilet flusher is restructuring in the sitting so that the basis of the ordinary, the automatic flush after use once, simple and reliable. When not in power source co mpletely disconnected, with energy-saving, easy to use, long life chip advantage. (1) circuit automatic flush toilet circuit from the power circuit, monostable solenoid valve and control circuit, as shown 1-47 Fig. Power circuit consists of step-down capacitor C1, rectifier diode VD1, Zener diode and capacitor C2 vs other components.

(2) the work process open toilet lid, the switch S is turned on, AC 220V voltage by cI Buck, VD1 rectifier, vs regulator and G after filtering, to provide the power supply circuit.. . : Monostable circuit from when base integrated circuit lc and relevant peripheral components. foot trigger terminal 1C initial voltage by Rz, R3 partial pressure is higher than after Vcc/3, lC the pin output low, the single-shot in the steady state, the relay K is not action, large-capacity capacitor is charged 0 full power.

After use, when the toilet lid cover, switch S off, the circuit power outages, due to the isolation of VD2 charge cz Rz on the quickly let go and Po. lC of pin goes low is triggered. In this case the bulk capacitor G is the IC supply through diode VD3, one-shot circuit is triggered transient backward people, ICs pin goes high, the relay K leisure together.

After K closed self-locking, so that the circuit to restore power supply, K closed connected to electric solenoid valve Y, start flushing. Meanwhile, the power supply via a resistor horse C3 charging, when charging so C3 rises to the potential of pin IC 2Vcc/3 resistance, temporary end state, lC of foot turned back low, the relay K release, K OFF, the The entire circuit power, flush ends.

Used in the circuit of the thyristor VTH G discharge, ensure that only flush once. When the IC foot just flip from low to high, VTH is triggered conduction, the G discharge voltage drops 2 ~ 3V. If set G discharge circuit, the lC after the transient, the relay K release put, K suddenly disconnected the circuit energized, ICs feet and jump into a low, G by VD3 supplies power to lC, single steady circuit again and again by the trigger, and pull the relay K, and so forth cycle.