line following robot identifying the line

To enable a line-following robot to identify the line, it is essential to first detect the line itself. Several methods can be employed to distinguish a black line on a white background, or vice versa. One effective approach is to utilize an array of Light Dependent Resistors (LDRs) to monitor the levels of light reflection. A black line will absorb more light and reflect less compared to a white surface.

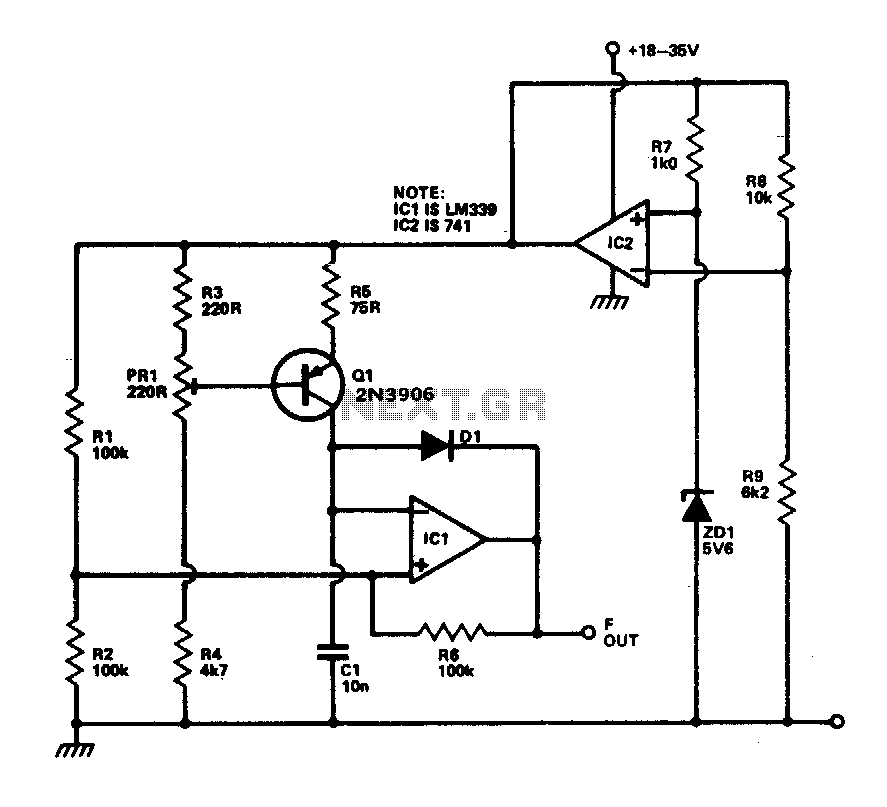

The circuit for a line-following robot typically incorporates an array of LDRs configured in a way that allows for differential light sensing. The LDRs are arranged in a linear fashion along the front side of the robot. When the robot is positioned over the line, the LDRs that are directly over the black line will show a lower resistance due to reduced light reflection, while the LDRs over the white background will exhibit higher resistance due to increased light reflection.

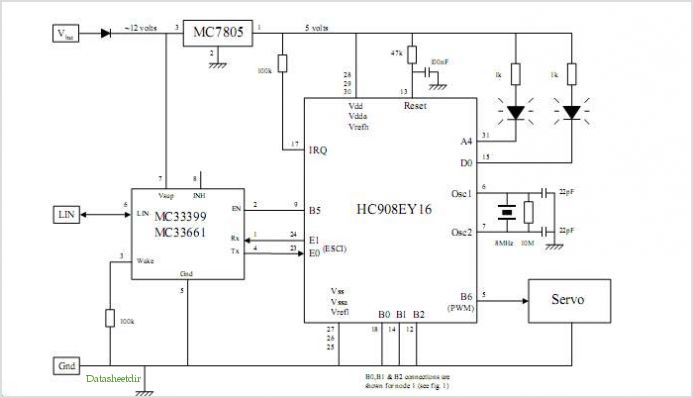

To process the signals from the LDRs, a microcontroller is employed. The microcontroller reads the voltage levels from each LDR, which can be converted into digital signals using an Analog-to-Digital Converter (ADC) if necessary. Based on the input from the LDRs, the microcontroller can determine the position of the line relative to the robot. If the robot detects that the left LDRs are receiving less light than the right ones, it can adjust its movement to the right, and vice versa.

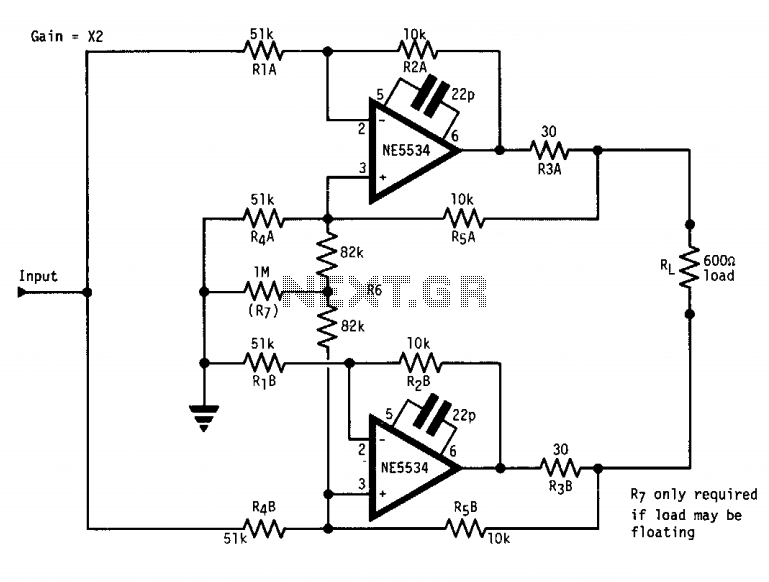

Additional components in the circuit may include operational amplifiers to amplify the LDR signals for better sensitivity, and a motor driver circuit to control the motors that steer the robot. The motor driver receives commands from the microcontroller based on the processed LDR data, allowing for precise maneuvers along the line.

For optimal performance, calibration of the LDRs may be necessary to account for varying ambient light conditions. This can be achieved by programming the microcontroller to establish baseline readings under different lighting conditions, thus allowing the robot to adapt its line-following behavior accordingly.

In summary, the line-following robot utilizes an LDR array for line detection, a microcontroller for processing the signals, and a motor driver for executing movement commands, forming an integrated system capable of navigating along predefined paths efficiently.To follow the line robot need to identify the line first. Well there are few things you can do to identify a black line on white background or vice versa. One way is use LDR array and tracks the light reflection level. Black line will not reflect the light as white color. Or you can.. 🔗 External reference

The circuit for a line-following robot typically incorporates an array of LDRs configured in a way that allows for differential light sensing. The LDRs are arranged in a linear fashion along the front side of the robot. When the robot is positioned over the line, the LDRs that are directly over the black line will show a lower resistance due to reduced light reflection, while the LDRs over the white background will exhibit higher resistance due to increased light reflection.

To process the signals from the LDRs, a microcontroller is employed. The microcontroller reads the voltage levels from each LDR, which can be converted into digital signals using an Analog-to-Digital Converter (ADC) if necessary. Based on the input from the LDRs, the microcontroller can determine the position of the line relative to the robot. If the robot detects that the left LDRs are receiving less light than the right ones, it can adjust its movement to the right, and vice versa.

Additional components in the circuit may include operational amplifiers to amplify the LDR signals for better sensitivity, and a motor driver circuit to control the motors that steer the robot. The motor driver receives commands from the microcontroller based on the processed LDR data, allowing for precise maneuvers along the line.

For optimal performance, calibration of the LDRs may be necessary to account for varying ambient light conditions. This can be achieved by programming the microcontroller to establish baseline readings under different lighting conditions, thus allowing the robot to adapt its line-following behavior accordingly.

In summary, the line-following robot utilizes an LDR array for line detection, a microcontroller for processing the signals, and a motor driver for executing movement commands, forming an integrated system capable of navigating along predefined paths efficiently.To follow the line robot need to identify the line first. Well there are few things you can do to identify a black line on white background or vice versa. One way is use LDR array and tracks the light reflection level. Black line will not reflect the light as white color. Or you can.. 🔗 External reference