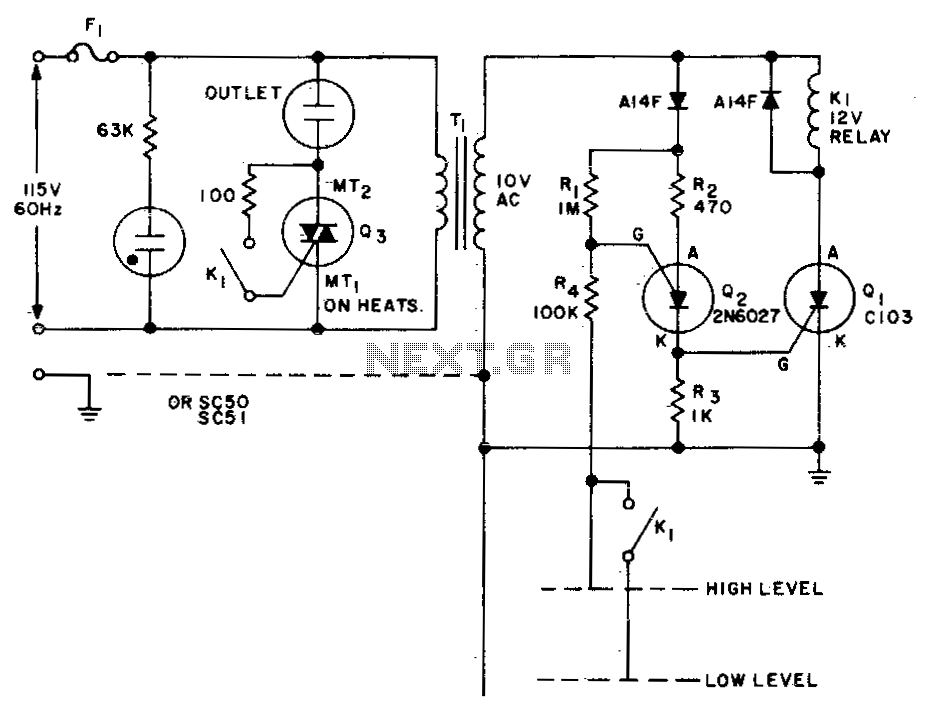

Liquid level control

This circuit is designed to maintain the fluid level of a liquid between two predetermined points. It features two operational modes for either filling or emptying the container, which can be achieved by simply reversing the connections of relay K1. The loads in this system can include electric motors or solenoid-operated valves that function using alternating current (AC) power. Liquid level detection is facilitated by two metal probes, one to sense the high level and the other to detect the low level. Additionally, an inversion of the logic for maintaining a filled container can be accomplished by substituting the normally open contact on the gate of transistor Q3 with a normally closed contact.

This fluid level control circuit employs a simple yet effective relay-based system to manage liquid levels. The two metal probes act as sensors, which are placed at the desired high and low fluid levels within the container. When the liquid reaches the high-level probe, it triggers the circuit to stop filling, while the low-level probe initiates the filling process when the liquid drops below this point.

Relay K1 is central to the operation of this circuit. In its standard configuration, it allows for the flow of current to either fill or empty the container based on the state of the probes. When the circuit is in the filling mode, the relay activates the electric motor or solenoid valve to introduce liquid into the container. Conversely, when in the emptying mode, the relay switches the operation to drain the liquid.

The transistor Q3 serves as a control element, and its gate can be manipulated to alter the logic of the system. By replacing the normally open contact with a normally closed contact, the circuit can be configured to maintain a full container, reversing the operational logic to suit specific application needs.

Overall, this circuit provides a versatile solution for liquid level management, allowing for efficient control of fluid dynamics in various industrial and domestic applications.Use this circuit to keep the fluid level of a liquid between two fixed points. Two modes, for filling or emptying are possible by simple reversing the contact connections of Kl. The loads can be either electric motors or solenoid operated valves, operating from ac power. Liquid level detection is accomplished by two metal probes, one measuring the high level and the other the low level An inversion of the logic (keeping the container filled) can be accomplished by replacing the normally open contact on the gate of Q3 with a normally closed contact. 🔗 External reference

This fluid level control circuit employs a simple yet effective relay-based system to manage liquid levels. The two metal probes act as sensors, which are placed at the desired high and low fluid levels within the container. When the liquid reaches the high-level probe, it triggers the circuit to stop filling, while the low-level probe initiates the filling process when the liquid drops below this point.

Relay K1 is central to the operation of this circuit. In its standard configuration, it allows for the flow of current to either fill or empty the container based on the state of the probes. When the circuit is in the filling mode, the relay activates the electric motor or solenoid valve to introduce liquid into the container. Conversely, when in the emptying mode, the relay switches the operation to drain the liquid.

The transistor Q3 serves as a control element, and its gate can be manipulated to alter the logic of the system. By replacing the normally open contact with a normally closed contact, the circuit can be configured to maintain a full container, reversing the operational logic to suit specific application needs.

Overall, this circuit provides a versatile solution for liquid level management, allowing for efficient control of fluid dynamics in various industrial and domestic applications.Use this circuit to keep the fluid level of a liquid between two fixed points. Two modes, for filling or emptying are possible by simple reversing the contact connections of Kl. The loads can be either electric motors or solenoid operated valves, operating from ac power. Liquid level detection is accomplished by two metal probes, one measuring the high level and the other the low level An inversion of the logic (keeping the container filled) can be accomplished by replacing the normally open contact on the gate of Q3 with a normally closed contact. 🔗 External reference