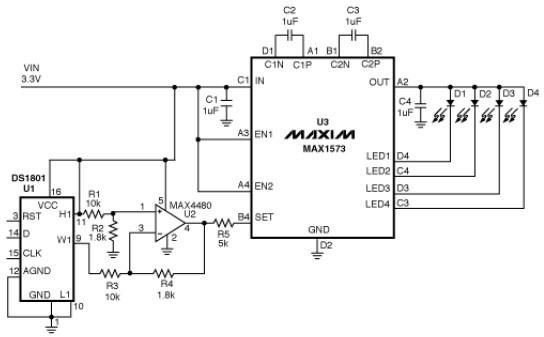

MAX1573 white led driver electronic project schematic

This white LED driver circuit operates up to four white LEDs in parallel from a 3.3V power source, adjusting the total LED current from 1mA to 106mA in 64 steps of 1dB each. The brightness control of the LEDs is managed by operational amplifier U2, which monitors the voltage difference between the high-side voltage and the wiper voltage of digital potentiometer U1. The operational amplifier multiplies this voltage by a gain to establish the maximum output current. A zero resistance at the W1 terminal of the potentiometer corresponds to the minimum LED current and thus the lowest brightness. Since the SET voltage is fixed at 0.6V, any change in voltage at the left side of resistor R5 affects ISET, leading to variations in LED current and brightness levels. Resistor R5 determines the maximum LED current using the formula R5 = 215 x 0.6 / ILED(Desired), where ILED is the current through a single LED. U1 is a digital potentiometer with a logarithmic taper and an analog voltage wiper, with each tap representing 1dB of attenuation between pins H1 and W1 (pins 11 and 9).

The LED driver circuit is designed to provide precise control over the brightness of multiple white LEDs, making it suitable for applications requiring variable lighting conditions. The use of a 3.3V source ensures compatibility with low-voltage systems, while the ability to adjust the current in 64 discrete steps allows for fine-tuning of brightness levels.

Operational amplifier U2 plays a critical role in the feedback loop, ensuring that the output current remains stable and proportional to the input from the digital potentiometer U1. The logarithmic taper of the digital potentiometer allows for a more natural perception of brightness changes, as human eyes perceive light intensity on a logarithmic scale.

The fixed SET voltage of 0.6V is a key parameter in determining the performance of the circuit. By adjusting the resistance of R5, the maximum current flowing through the LEDs can be tailored to the specific requirements of the application, allowing for flexibility in LED selection and desired brightness levels. This adaptability makes the circuit ideal for various lighting applications, including decorative lighting, indicator lights, or even task lighting where adjustable brightness is essential.

In summary, this LED driver circuit combines a low-voltage operation with advanced brightness control features, ensuring efficient and effective LED management for a wide range of electronic applications.This white led driver circuit circuit drives as many as four white LEDs in parallel from a 3. 3V source, and adjusts the total LED current from 1mA to 106mA, in 64 steps of 1dB each. To control the LED brightness, op amp U2 monitors the difference between the high-side voltage and the wiper voltage of digital potentiometer U1. The op amp then mult iplies that voltage by a gain to set the maximum output current. Zero resistance at the pot`s W1 terminal corresponds to minimum LED current, and therefore minimum brightness. Because the SET voltage is fixed (at 0. 6V), any voltage change at the left side of R5 changes ISET, and the resulting change in LED currents changes their brightness level.

R5 sets the maximum LED current: R5 = 215x0. 6/ILED(Desired) (ILED is the current through one LED). U1 integrated circuit is a digital potentiometer with logarithmic taper and an analog-voltage wiper for which each tap corresponds to 1dB of attenuation between H1 and W1 (pins 11 and 9). 🔗 External reference

The LED driver circuit is designed to provide precise control over the brightness of multiple white LEDs, making it suitable for applications requiring variable lighting conditions. The use of a 3.3V source ensures compatibility with low-voltage systems, while the ability to adjust the current in 64 discrete steps allows for fine-tuning of brightness levels.

Operational amplifier U2 plays a critical role in the feedback loop, ensuring that the output current remains stable and proportional to the input from the digital potentiometer U1. The logarithmic taper of the digital potentiometer allows for a more natural perception of brightness changes, as human eyes perceive light intensity on a logarithmic scale.

The fixed SET voltage of 0.6V is a key parameter in determining the performance of the circuit. By adjusting the resistance of R5, the maximum current flowing through the LEDs can be tailored to the specific requirements of the application, allowing for flexibility in LED selection and desired brightness levels. This adaptability makes the circuit ideal for various lighting applications, including decorative lighting, indicator lights, or even task lighting where adjustable brightness is essential.

In summary, this LED driver circuit combines a low-voltage operation with advanced brightness control features, ensuring efficient and effective LED management for a wide range of electronic applications.This white led driver circuit circuit drives as many as four white LEDs in parallel from a 3. 3V source, and adjusts the total LED current from 1mA to 106mA, in 64 steps of 1dB each. To control the LED brightness, op amp U2 monitors the difference between the high-side voltage and the wiper voltage of digital potentiometer U1. The op amp then mult iplies that voltage by a gain to set the maximum output current. Zero resistance at the pot`s W1 terminal corresponds to minimum LED current, and therefore minimum brightness. Because the SET voltage is fixed (at 0. 6V), any voltage change at the left side of R5 changes ISET, and the resulting change in LED currents changes their brightness level.

R5 sets the maximum LED current: R5 = 215x0. 6/ILED(Desired) (ILED is the current through one LED). U1 integrated circuit is a digital potentiometer with logarithmic taper and an analog-voltage wiper for which each tap corresponds to 1dB of attenuation between H1 and W1 (pins 11 and 9). 🔗 External reference