H-bridge of 40N60 mini-brick IGBTs

This first DRSSTC evolved from the ISSTC work previously undertaken. After discussions with Jimmy Hynes, the creator of the first DRSSTC, it was decided to implement a modified design. Hynes' DRSSTC utilized an oscillator to produce a high-frequency signal for the coil, approximately 66 kHz. Preferring not to use voltage-controlled oscillators (VCOs) for tuning, feedback from the secondary coil was employed to ensure the driver remained in tune, necessitating tuning of the primary circuit to this frequency. The initial feedback design was straightforward, as depicted in the first schematic. The second schematic represents a standard H-bridge configuration. An important modification to this basic controller involved adding a JK flip-flop to synchronize the interrupter's turn-off with the feedback zero crossing. This adjustment is crucial to prevent the interrupter from disabling the gate drivers during an RF half-cycle, where current could peak significantly. DRSSTCs depend on soft-switching due to the resonant load, avoiding hard switching of the high currents in the primary circuit to protect the IGBTs. The flip-flop ensures this protection. The H-bridge schematic remains largely unchanged, now incorporating a voltage doubler at 140 VAC with two 22,000 µF, 200 VDC electrolytic capacitors, which are larger than necessary but were available. The GDTs are constructed using Cat-5 networking cable wrapped around a ferrite core, with ten turns and a configuration that parallels the "white" conductors while pairing the "color" conductors in series, resulting in two outputs and a transformer with high primary to secondary coupling. The current H-bridge is crafted from copper-clad material, hand-etched with a rotary tool, utilizing both sides of the clad in parallel to enhance conductor surface area. Previous spark photos indicate sparks reaching lengths of 55 inches, with one image capturing an IGBT failure and the resulting blue illumination from a fuse explosion. As of December 18, 2004, the project remains under construction due to numerous modifications. The impetus for these changes was the desire to experiment with lower tank impedance, leading to quadrupling the tank capacitance to 0.3 µF and reducing the primary turns to four. A new 6.5-inch OD secondary was built using 26 AWG wire, operating at approximately 130 kHz. The new control board features stacked gate drivers, suitable for this pulsed application but inadvisable in continuous wave systems. Recent tests recorded power at the outlet, showing the efficiency decline as the ON period increased.

This DRSSTC (Dual Resonant Solid State Tesla Coil) design showcases a blend of innovation and adaptation from previous models, emphasizing the importance of feedback mechanisms for optimal performance. The use of a JK flip-flop is a critical enhancement, ensuring that the gate drivers are not accidentally disabled during high current RF cycles, which could lead to damage. The implementation of soft-switching is essential in managing the substantial currents that flow through the primary circuit, protecting the IGBTs from thermal stress and potential failure.

The construction of the GDT (Gate Drive Transformer) with Cat-5 networking cable demonstrates a practical approach to achieving high coupling efficiency. The choice of materials, including the copper-clad substrate for the H-bridge, reflects a focus on maximizing surface area for current handling, which is vital in high-power applications like DRSSTCs. The capacitors used in the voltage doubler circuit play a significant role in voltage regulation and energy storage, crucial for maintaining the performance of the coil.

The ongoing modifications to the coil, including adjustments to capacitance and inductance, highlight the iterative nature of the design process in high-voltage applications. The exploration of different configurations and components is indicative of a commitment to optimizing performance and efficiency. The recorded data from recent tests serves as a valuable resource for understanding the relationship between input power and operational efficiency, guiding future iterations of the design. The visual documentation of spark generation and component failures provides insight into the operational limits and challenges faced in the development of high-energy Tesla coils.This first DRSSTC of mine evolved from the ISSTC work I had been doing at the time. Talking with Jimmy Hynes, who built the first DRSSTC, I decided I would give it a try, though with some changes from his design. Jimmy`s DRSSTC used an oscillator to generate the high frequency signal that drives the coil (about 66khz for his coil, I believe).

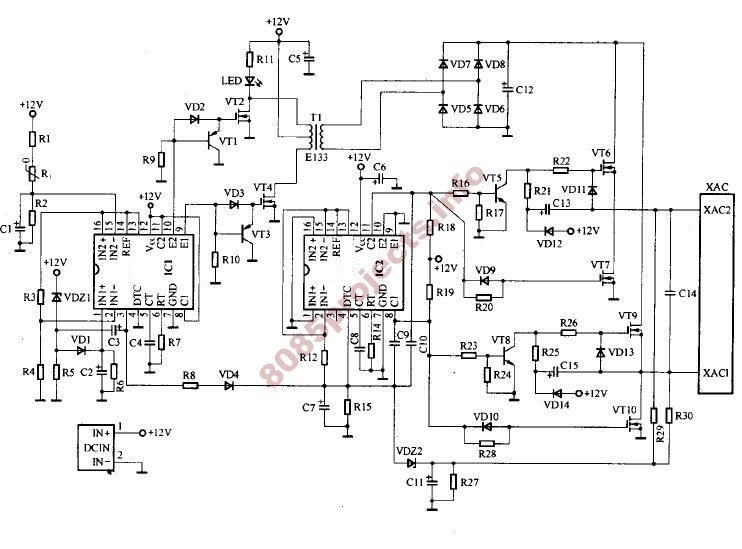

Sinc e I`m not a big fan of using VCOs to tune tesla coils, I would use feedback from the secondary coil itself, ensuring that my driver was always in tune. I would then have to tune the primary circuit to this operating frequency. My feedback design started out very simple, and is seen below: The first schematic was what I originally used for my DRSSTCs.

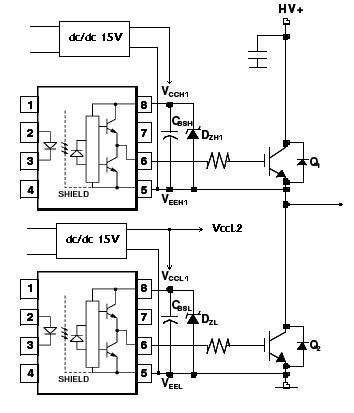

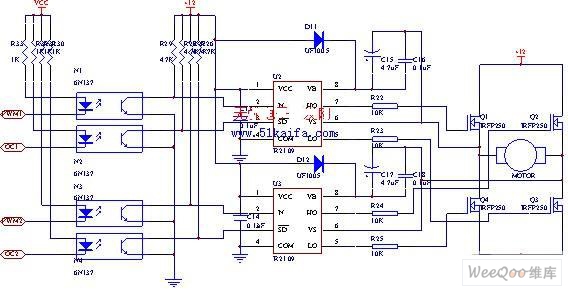

The second schematic is just a standard H-bridge, nothing too special there. I eventually made an important change to this very basic controller. The change was the addition of a JK flip flop, which would synchronize the interrupter turn off to the feedback zero crossing. This is important because with out this, the interrupter can disable the gate drivers during an RF half-cycle, where current could be very high.

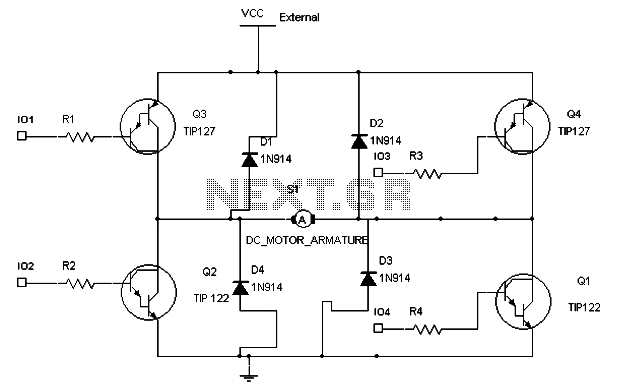

DRSSTCs rely on soft-switching, due to the resonant load. We try to avoid hard switching the several hundreds of amps that may be flowing through the primary circuit, as this is very hard on the IGBTs. Anyway, the flip flop ensures that this should not happen. Below is the schematic (updated 3/17/05): I still use the same basic schematic for the H-bridge, except now I use a voltage doubler at 140VAC, using a pair of 22000uf 200VDC electrolytic capacitors.

These capacitors are much larger than needed, but they are what I had on hand. Here is how I make my GDTs. I take some cat-5 networking cable, and wrap 10 turns of it around a ferrite core. I then parallel all of the "white" conductors, and then series up pairs of the "color" conductors. This gives 2 outputs, and a 1:2:2 transformer with very high primary to secondary coupling. Here is my current H-bridge. It is made from copper clad, etched by hand with my dremel rotary tool. Both sides of the clad are used in parallel to increase conductor surface area. Here are some older spark photos. Some sparks were as long as 55" in length. Notice in one pic, the blue illumination of the background. I caught an IGBT failure on camera, and that blue light is from the fuse exploding violently! 12/18/04: This project is actually still under construction. This is why there are not many construction pictures. because the coil has had many changes made to it. What brought about this construction Well, my desire to try new things. Recently I have been curious to try a lower tank impedance (Z=sqrt(L/C). So I quadrupled my tank capacitance to. 3uF, and reduced my primary to 4 turns. Additionally, I built a new, 6. 5" OD secondary using 26awg, the whole thing runs at around 130khz. Here is the new control board I etched for this coil. Notice how I stacked the gate drivers. This is ok in a pulsed application like this, where driver heating is not considerable. You must not do this in a CW system! I ran the new setup (6. 5"x22" secondary, . 3uf MMC) in the garage yesterday and recorded some data. The % of VAC is of 140VAC input which is then doubled to 400VDC max. Power into the coil was recorded at the power outlet. Notice how poor the efficiency is as the ON period increases! 🔗 External reference

This DRSSTC (Dual Resonant Solid State Tesla Coil) design showcases a blend of innovation and adaptation from previous models, emphasizing the importance of feedback mechanisms for optimal performance. The use of a JK flip-flop is a critical enhancement, ensuring that the gate drivers are not accidentally disabled during high current RF cycles, which could lead to damage. The implementation of soft-switching is essential in managing the substantial currents that flow through the primary circuit, protecting the IGBTs from thermal stress and potential failure.

The construction of the GDT (Gate Drive Transformer) with Cat-5 networking cable demonstrates a practical approach to achieving high coupling efficiency. The choice of materials, including the copper-clad substrate for the H-bridge, reflects a focus on maximizing surface area for current handling, which is vital in high-power applications like DRSSTCs. The capacitors used in the voltage doubler circuit play a significant role in voltage regulation and energy storage, crucial for maintaining the performance of the coil.

The ongoing modifications to the coil, including adjustments to capacitance and inductance, highlight the iterative nature of the design process in high-voltage applications. The exploration of different configurations and components is indicative of a commitment to optimizing performance and efficiency. The recorded data from recent tests serves as a valuable resource for understanding the relationship between input power and operational efficiency, guiding future iterations of the design. The visual documentation of spark generation and component failures provides insight into the operational limits and challenges faced in the development of high-energy Tesla coils.This first DRSSTC of mine evolved from the ISSTC work I had been doing at the time. Talking with Jimmy Hynes, who built the first DRSSTC, I decided I would give it a try, though with some changes from his design. Jimmy`s DRSSTC used an oscillator to generate the high frequency signal that drives the coil (about 66khz for his coil, I believe).

Sinc e I`m not a big fan of using VCOs to tune tesla coils, I would use feedback from the secondary coil itself, ensuring that my driver was always in tune. I would then have to tune the primary circuit to this operating frequency. My feedback design started out very simple, and is seen below: The first schematic was what I originally used for my DRSSTCs.

The second schematic is just a standard H-bridge, nothing too special there. I eventually made an important change to this very basic controller. The change was the addition of a JK flip flop, which would synchronize the interrupter turn off to the feedback zero crossing. This is important because with out this, the interrupter can disable the gate drivers during an RF half-cycle, where current could be very high.

DRSSTCs rely on soft-switching, due to the resonant load. We try to avoid hard switching the several hundreds of amps that may be flowing through the primary circuit, as this is very hard on the IGBTs. Anyway, the flip flop ensures that this should not happen. Below is the schematic (updated 3/17/05): I still use the same basic schematic for the H-bridge, except now I use a voltage doubler at 140VAC, using a pair of 22000uf 200VDC electrolytic capacitors.

These capacitors are much larger than needed, but they are what I had on hand. Here is how I make my GDTs. I take some cat-5 networking cable, and wrap 10 turns of it around a ferrite core. I then parallel all of the "white" conductors, and then series up pairs of the "color" conductors. This gives 2 outputs, and a 1:2:2 transformer with very high primary to secondary coupling. Here is my current H-bridge. It is made from copper clad, etched by hand with my dremel rotary tool. Both sides of the clad are used in parallel to increase conductor surface area. Here are some older spark photos. Some sparks were as long as 55" in length. Notice in one pic, the blue illumination of the background. I caught an IGBT failure on camera, and that blue light is from the fuse exploding violently! 12/18/04: This project is actually still under construction. This is why there are not many construction pictures. because the coil has had many changes made to it. What brought about this construction Well, my desire to try new things. Recently I have been curious to try a lower tank impedance (Z=sqrt(L/C). So I quadrupled my tank capacitance to. 3uF, and reduced my primary to 4 turns. Additionally, I built a new, 6. 5" OD secondary using 26awg, the whole thing runs at around 130khz. Here is the new control board I etched for this coil. Notice how I stacked the gate drivers. This is ok in a pulsed application like this, where driver heating is not considerable. You must not do this in a CW system! I ran the new setup (6. 5"x22" secondary, . 3uf MMC) in the garage yesterday and recorded some data. The % of VAC is of 140VAC input which is then doubled to 400VDC max. Power into the coil was recorded at the power outlet. Notice how poor the efficiency is as the ON period increases! 🔗 External reference