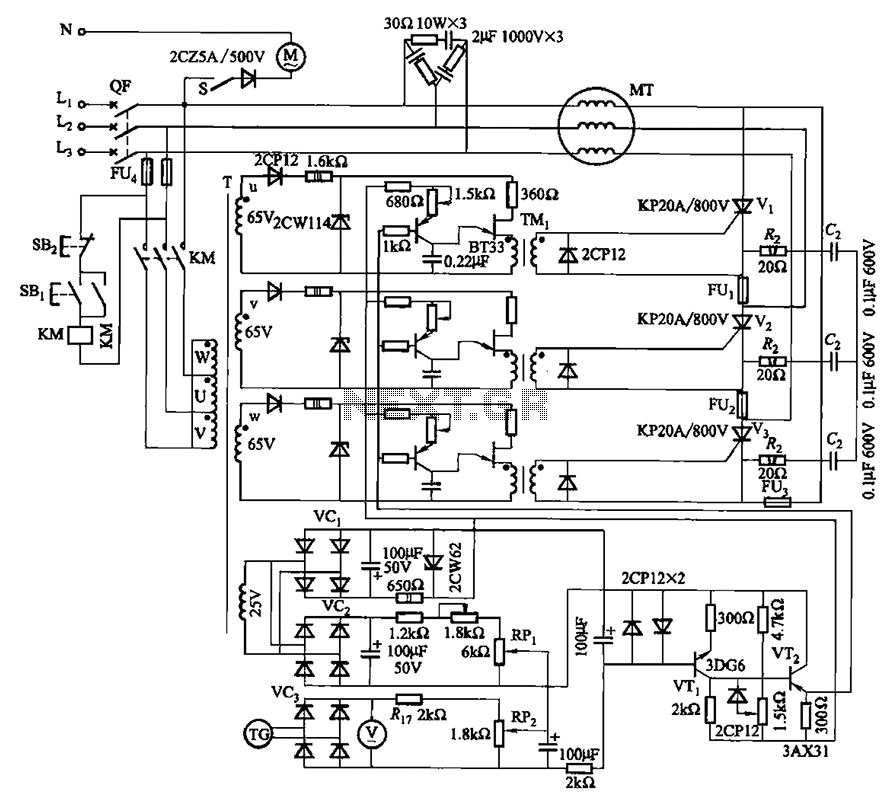

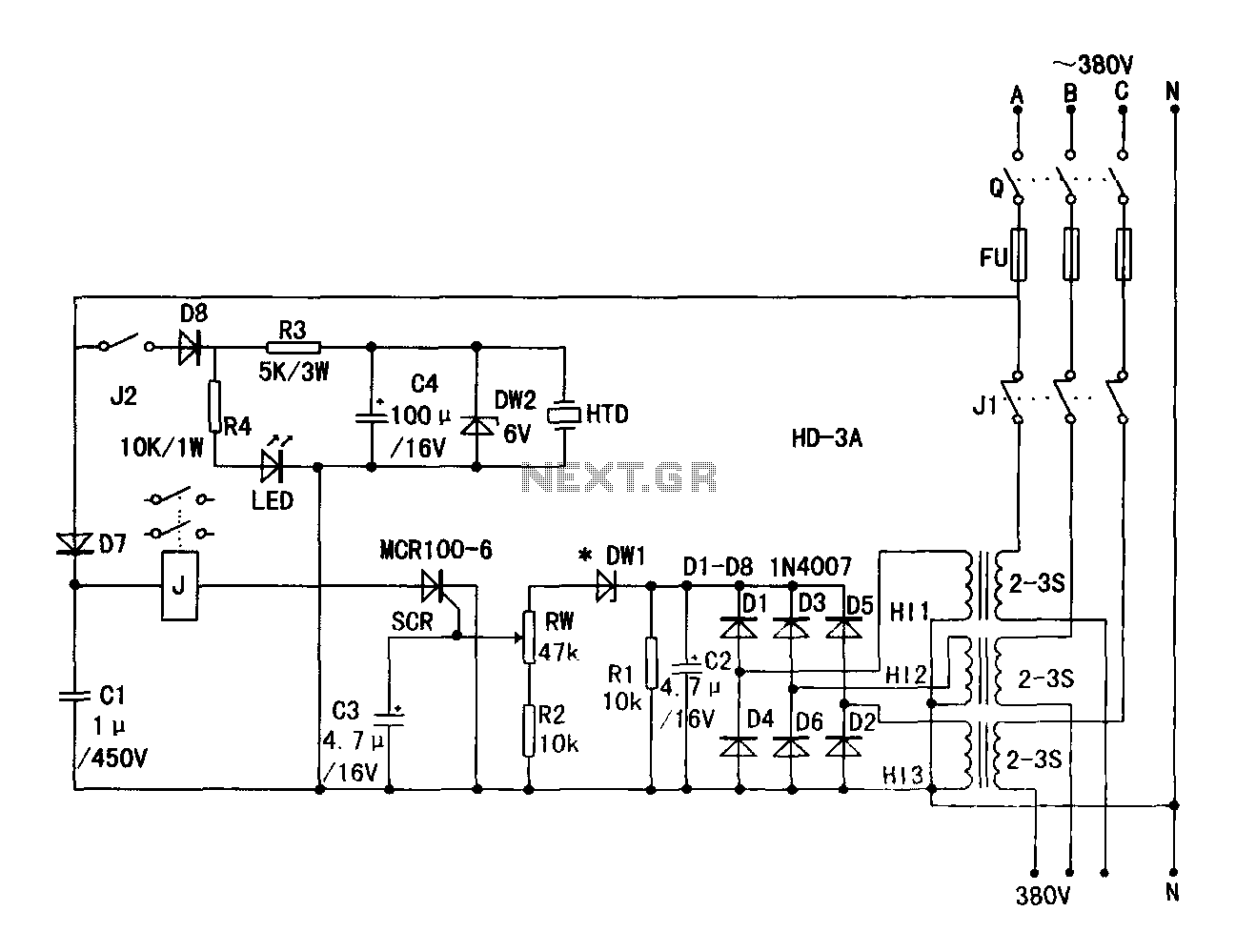

HD a 3A limit energy-saving three-phase power protection circuit

A current transformer H11-3 needs to be constructed. Select a transformer core with a minimum power rating of 2W for the first secondary winding. Use enameled wire with a diameter of 0.12 mm and wind approximately 1000 turns. The primary current should be in the range of 1 to 4 mA. Additionally, use plastic wire for about 2 to 3 turns. Current transformers can also be completed, and the induced voltage of the finished current transformer is relatively high.

The H11-3 current transformer is designed to accurately measure alternating current (AC) by producing a proportional output current or voltage. The selection of a transformer core with a minimum rating of 2W is crucial to ensure that the transformer can handle the expected power levels without saturation, which could lead to inaccurate readings. The first secondary winding is essential for establishing the transformer's output characteristics.

Using enameled wire with a diameter of 0.12 mm for the winding is a common practice in transformer design, as it provides good insulation and allows for a high number of turns within a limited space. The specification of approximately 1000 turns for the secondary winding is aimed at achieving the desired turns ratio, which is critical for the transformation of current levels from the primary to the secondary side. The primary current range of 1 to 4 mA indicates that this transformer is likely intended for low-power applications, where precision in current measurement is necessary.

The mention of using plastic wire for an additional 2 to 3 turns may refer to a secondary winding that serves a different purpose, such as providing feedback or enhancing the transformer's response characteristics. This could be particularly useful in applications requiring a quick response to changes in current.

It is important to note that the induced voltage of the finished current transformer can be relatively high, which necessitates careful handling and consideration of the circuit design to prevent damage to connected components and ensure safe operation. Proper insulation and protective measures should be implemented to safeguard against potential overvoltage conditions. Overall, the design and construction of the H11-3 current transformer require attention to detail and adherence to electrical standards to ensure reliable performance in measuring AC currents.Current Transformer H11-3 need be made. Choose not less than 2W transformer core, the first secondary winding. With µ0.12mm enameled wire around 1000 turns. Primary use µ1 ~ 4m m plastic wire around 2 3 turns to. Current transformers may also be finished. Finished current transformer induced voltage is relatively high.

The H11-3 current transformer is designed to accurately measure alternating current (AC) by producing a proportional output current or voltage. The selection of a transformer core with a minimum rating of 2W is crucial to ensure that the transformer can handle the expected power levels without saturation, which could lead to inaccurate readings. The first secondary winding is essential for establishing the transformer's output characteristics.

Using enameled wire with a diameter of 0.12 mm for the winding is a common practice in transformer design, as it provides good insulation and allows for a high number of turns within a limited space. The specification of approximately 1000 turns for the secondary winding is aimed at achieving the desired turns ratio, which is critical for the transformation of current levels from the primary to the secondary side. The primary current range of 1 to 4 mA indicates that this transformer is likely intended for low-power applications, where precision in current measurement is necessary.

The mention of using plastic wire for an additional 2 to 3 turns may refer to a secondary winding that serves a different purpose, such as providing feedback or enhancing the transformer's response characteristics. This could be particularly useful in applications requiring a quick response to changes in current.

It is important to note that the induced voltage of the finished current transformer can be relatively high, which necessitates careful handling and consideration of the circuit design to prevent damage to connected components and ensure safe operation. Proper insulation and protective measures should be implemented to safeguard against potential overvoltage conditions. Overall, the design and construction of the H11-3 current transformer require attention to detail and adherence to electrical standards to ensure reliable performance in measuring AC currents.Current Transformer H11-3 need be made. Choose not less than 2W transformer core, the first secondary winding. With µ0.12mm enameled wire around 1000 turns. Primary use µ1 ~ 4m m plastic wire around 2 3 turns to. Current transformers may also be finished. Finished current transformer induced voltage is relatively high.